蔬果嫁接苗省工生產模式

2020/09/22 @臺灣

示意圖

蔬果嫁接苗省工生產模式

Labor-saving grafting system for vegetable seedlings production

國立宜蘭大學園藝學系

Department of Horticulture, National Ilan University

研究團隊研發「軟夾式蔬果種苗嫁接機」及「嫁接苗癒合裝置」,並進行機械用根砧苗及接穗苗規格化育成研究。「軟夾式蔬果種苗嫁接機」單株番茄苗作業時間9.1~12.5 秒,作業能量395 株/ 小時,嫁接成功率可達92.5%。透過砧穗苗規格化育成技術發展,使用「軟夾式蔬果種苗嫁接機」進行嫁接,搭配高效節能多時變設定的「嫁接苗癒合裝置」,可大幅提升嫁接苗株之嫁接成功率及苗癒成率,達到蔬果嫁接種苗省工化生產之目的。

The research team has developed "a soft-clip fruit-bearing vegetable seedling grafting robotic system” and "an energy-saving healing device”, and also researched the automatic standardized cultivation of rootstock and scion. The "soft-clip fruit-bearing vegetable seedling grafting robotic system" takes 9.1~12.5 seconds to process single tomato plant, with an operating capacity of 395 plants per hour and a success rate of 92.5%. By developing standardized cultivation of rootstock and scion, we use “soft-clip fruit-bearing vegetable seedling grafting robotic system” to graft, together with "energy-saving healing device”, featuring high-efficiency and multi-time-varying settings, to greatly increase the grafting success rate and seedlings healing rate, thus achieving a labor-saving grafting system for vegetable seedlings production.

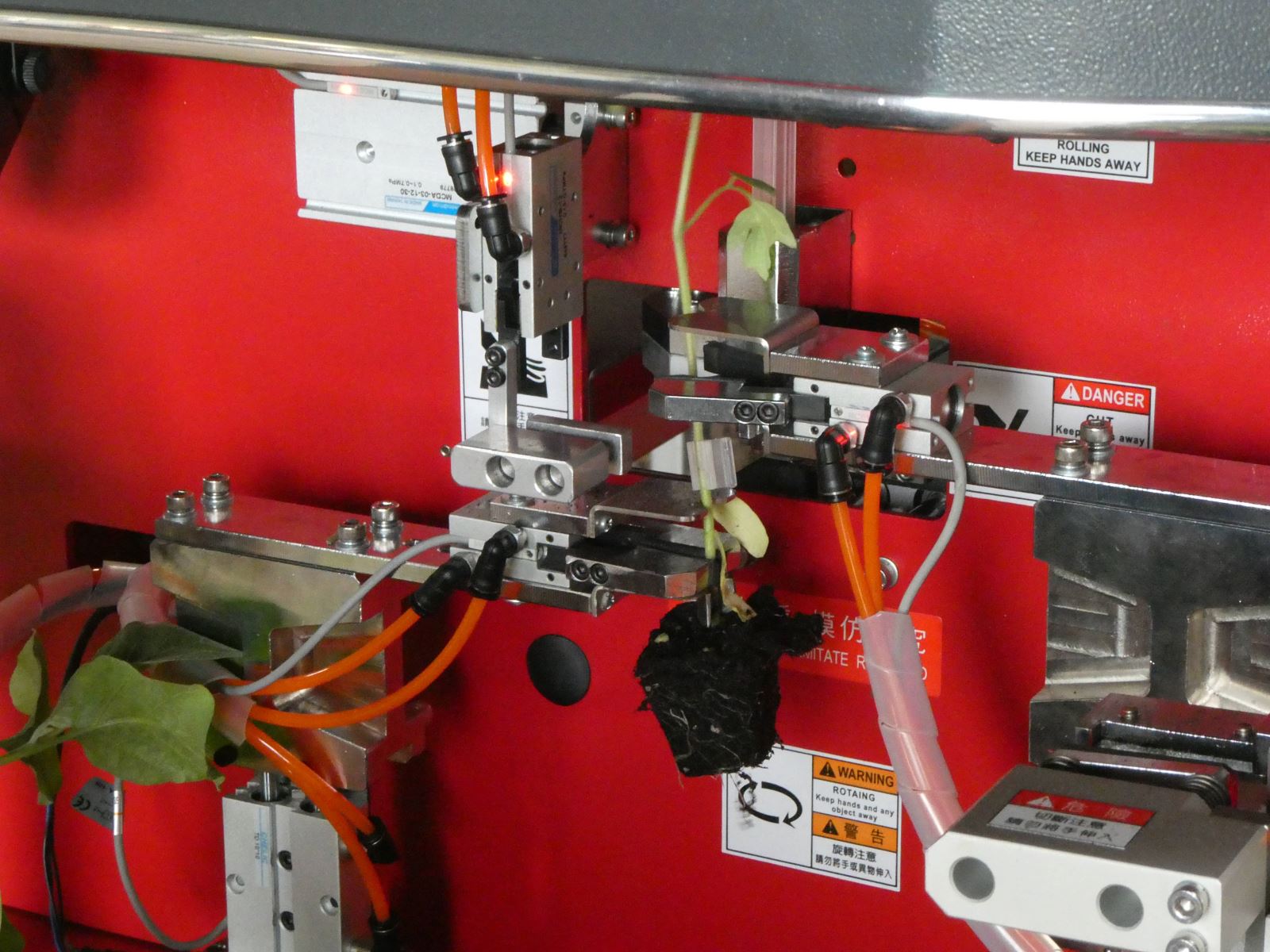

圖1、軟夾式蔬果種苗嫁接機。

Fig. 1. A soft-clip fruit-bearing vegetable seedling grafting robotic system

圖2、嫁接苗癒合室。

Fig. 2. An energy-saving healing device.

圖3、完成茄子根砧與番茄接穗自動化連續嫁接。

Fig. 3. Completing the automatic and continuous grafting of tomato scion onto eggplant rootstock.

圖4、茄子根砧與番茄接穗自動化嫁接示範。

Fig. 4. Demonstration of the automatic grafting of tomato scion onto eggplant rootstock.

資料來源

- 財團法人農業科技研究院彙整

- 台灣農業科技資源運籌管理學會《農業技術口碑好,南向出口有一套》成果手冊

文章摘譯